Hello readers,

Welcome to the AI For All newsletter! Today, we’ll be exploring how Audi is applying AI on its assembly line, MCP over MQTT, and more!

Also, an important update to the AI For All newsletter family: Starting this week, we’ve brought our AI and IoT newsletters together under one roof. That means more insights, fewer signups, and you’re automatically included.

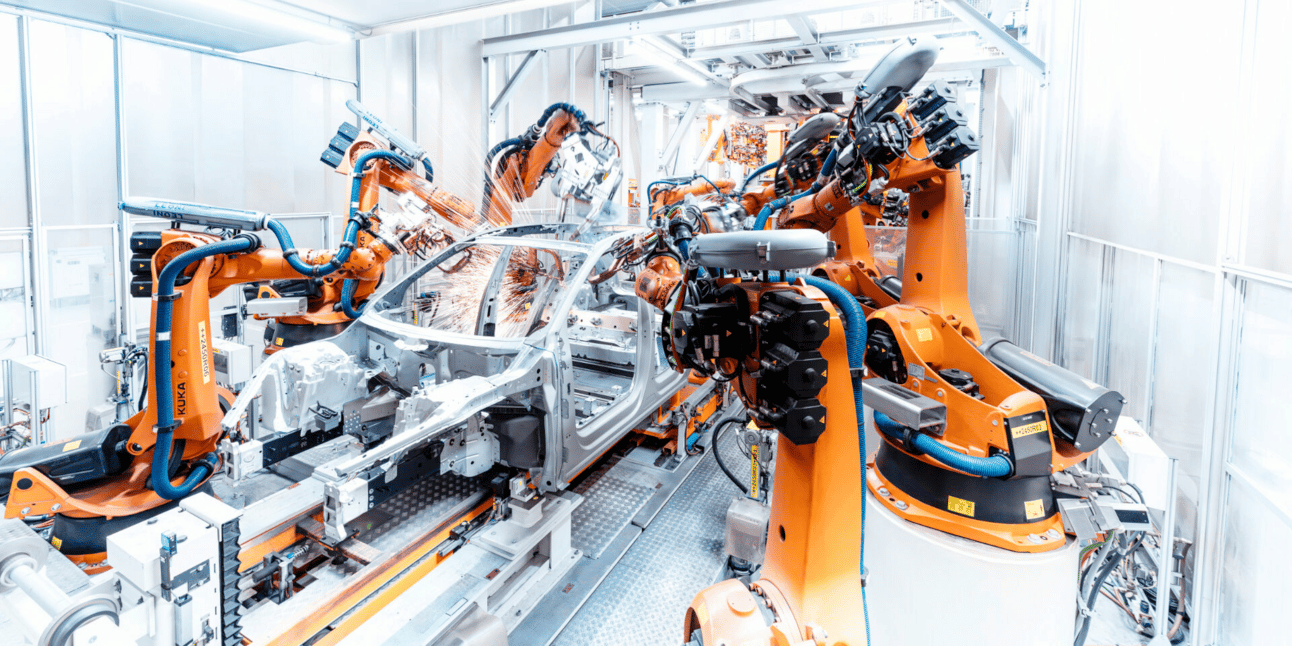

AI in Action: Audi’s AI part-pickers

At Audi’s Böllinger Höfe facility, artificial intelligence is being applied to streamline one of the most complex aspects of automotive manufacturing: the manual picking process, where workers select and retrieve the parts required to build a given vehicle. Audi Sport is working alongside researchers from the Fraunhofer Institutes to test AI-driven tools and robotics in a real-world production environment. The goal is to reduce inefficiencies, prevent errors, and ease physical strain on employees, particularly in low-volume, high-customization production like that of the Audi e-tron GT.

Employees wear smart glasses with infrared eye-tracking technology to reveal which parts of the picking process are most mentally taxing. That data helps the team understand where workers need the most support. Rather than implementing tech for tech’s sake, the goal is to match AI and robotics to the real, observed challenges of the workflow with an end goal of boosting both accuracy and ergonomic sustainability in the process.

“The central input comes from the workers themselves, who evaluate the benefits of artificial intelligence, sensor technology, and robotics in their familiar production environment."

In a designated lab area that replicates the actual “supermarket” component storage system, Audi and its research partners are testing AI applications like computer vision to assist with part identification, as well as mobile robots equipped with advanced grippers and 3D sensors to handle material transport. These technologies are evaluated using real vehicle orders to ensure solutions are practical and scalable. With employees involved directly in testing and feedback, the AI tools being developed are not just innovative. They’re built to solve real problems in a production line setting.

🔥 Rapid Fire

Why AI acts so creepy when faced with being shut down

Microsoft-backed Builder faked its AI with Indian engineers, goes bankrupt

Amazon planning $10B investment in North Carolina for data center and AI campus

ChatGPT can now read your Google Drive and Dropbox

AI reveals hidden language patterns and likely authorship in the Bible

FDA rushed out agency-wide AI tool—it’s not going well

Alphabet CEO Sundar Pichai dismisses AI job fears, emphasizes expansion plans

📖 What We’re Reading

“IoT devices enable the digital world to perceive the physical environment by reporting data, while also allowing control and operation of physical-world devices through exposed interfaces to meet specific user needs. Currently, most IoT systems rely on the MQTT protocol for communication. The architectural design of MCP aligns closely with the "device model" concept in IoT, making it a promising solution for this domain. MCP not only integrates seamlessly with existing MQTT-based systems but also enhances the connection between devices and AI applications.”